Product Description:

Fused Aluminum Oxide, also commonly referred to as Fused Alumina or Fused Aluminum Oxides, is a high-quality, advanced material known for its exceptional hardness and durability. This industrial-grade abrasive is widely used in various applications including grinding, polishing, sandblasting, and refractory products. It is manufactured through the fusion of high-purity alumina in an electric arc furnace, resulting in a crystalline powder with superior physical and chemical properties.

One of the most notable characteristics of Fused Aluminum Oxide is its remarkable hardness, rated at 9 on the Mohs scale. This places it just below diamond, making it an ideal abrasive for cutting, grinding, and polishing hard materials such as metals, stones, ceramics, and glass. The hardness of Fused Alumina ensures excellent wear resistance and long service life, significantly enhancing the efficiency and cost-effectiveness of industrial processes.

The density of Fused Aluminum Oxide is approximately 3.95 grams per cubic centimeter (G/cm³). This relatively high density contributes to its substantial mass and strength, providing excellent stability during use. The dense nature of Fused Alumina also allows it to withstand extreme mechanical stresses and thermal shocks, which is crucial in high-temperature environments and demanding applications.

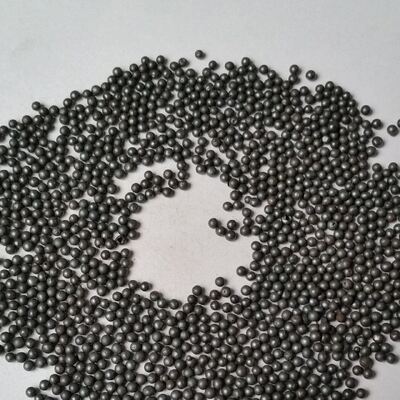

Fused Aluminum Oxide is typically available in particle sizes ranging from 2 to 3 millimeters. This specific particle size range offers a balanced combination of surface area and mass, making it suitable for various abrasive applications. The granules provide a consistent texture that ensures uniform abrasion and efficient material removal. The controlled particle size distribution helps optimize the performance of Fused Alumina in processes such as sandblasting, grinding wheels, and refractory linings.

In terms of appearance, Fused Alumina presents itself as a white to gray crystalline powder. This color variation depends on the purity and specific manufacturing processes used during fusion. The crystalline nature of the powder contributes to its sharp edges and angular particles, which are essential for effective abrasive action. The uniformity in appearance also reflects the high-quality standards maintained during the production of Fused Aluminum Oxide.

Chemically, Fused Aluminum Oxide is composed of aluminum oxide with the formula Al2O3. This chemical composition underpins its outstanding physical and chemical stability. Al2O3 is known for its excellent resistance to chemical corrosion and high melting point, making Fused Alumina suitable for use in harsh environments where chemical inertness and thermal stability are required. This makes it a preferred choice in refractory applications, where it serves as a key component in furnace linings, kiln furniture, and other high-temperature industrial equipment.

In summary, Fused Aluminum Oxide is a versatile and robust material characterized by a hardness of 9 Mohs, a density of 3.95 G/cm³, and a particle size of 2-3mm. Its white to gray crystalline powder appearance and chemical formula of Al2O3 highlight its high purity and quality. Known interchangeably as Fused Aluminium Oxide, Fused Aluminum Oxides, or Fused Alumina, this product is indispensable across numerous industries due to its superior abrasion resistance, thermal stability, and chemical inertness. Whether used in abrasive blasting, grinding, polishing, or refractory applications, Fused Aluminum Oxide consistently delivers excellent performance and reliability.

Features:

-

Product Name: Fused Aluminum Oxide

-

Chemical Formula: Al2O3

-

Material: Aluminum Oxide

-

Density: 3.95 G/cm³

-

Mohs Hardness: 9

-

Chemical Stability: Stable in acidic and alkaline environments

-

Also known as Fused Aluminium Oxide and Brown Corundum

-

High durability and resistance due to its chemical stability

-

Widely used in abrasive applications as Fused Aluminum Oxides

Technical Parameters:

|

Product Name

|

Fused Aluminum Oxide

|

|

Main Material

|

Aluminum Oxide

|

|

Material

|

Aluminum Oxide

|

|

Particle Size

|

2-3mm

|

|

Chemical Stability

|

Stable In Acidic And Alkaline Environments

|

|

Electrical Resistivity

|

High Electrical Resistivity

|

|

Hardness

|

9 Mohs

|

|

Color

|

White To Gray

|

|

Appearance

|

White To Gray Crystalline Powder

|

|

For

|

Precision Casting Products

|

Applications:

The KMN Fused Aluminum Oxide (Model Number: F) is a high-quality blasting media widely used in various industrial applications due to its exceptional hardness and durability. Certified with ISO 9001, this product guarantees consistent quality and performance, making it an ideal choice for precision casting products. The fused aluminum oxides are available in a white to gray crystalline powder form, exhibiting a hardness of 9 Mohs, which ensures effective abrasive action in surface preparation and finishing processes.

Fused Alumina is extensively utilized in scenarios that demand high precision and reliability. It is commonly applied in the aerospace, automotive, and heavy machinery industries where surface treatment and cleaning of metal parts are critical. The abrasive properties of this blasting media make it perfect for removing rust, scale, and old coatings without damaging the base material. Additionally, its consistent particle size and hardness contribute to uniform surface profiling, essential for improving adhesion in subsequent painting or coating operations.

Brown Corundum, often used interchangeably with fused aluminum oxide, serves as a versatile abrasive for grinding, polishing, and sandblasting applications. It is especially beneficial in manufacturing environments where precision castings require meticulous surface finishing to meet stringent quality standards. The white to gray color of the KMN fused alumina allows for easy identification and quality control during processing.

With a supply capacity of 30,000 tons per year, KMN ensures timely delivery based on order quantity, accommodating minimum order requirements of 5 tons. Pricing is negotiable, and flexible payment terms such as T/T and L/C at sight are available to facilitate smooth transactions. This makes KMN’s fused aluminum oxide an economical and reliable choice for companies seeking high-performance blasting media for their precision casting products.

In summary, KMN's fused aluminum oxides are perfect for blasting, grinding, polishing, and surface preparation in precision casting and other demanding industrial applications. Their superior hardness, consistent quality, and compliance with ISO 9001 standards make them indispensable in scenarios where abrasive efficiency and reliability are paramount.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!